For my Design and Technology project during my A-level year we were set the task to design and make a product, with a great emphasis on sustainability. For this I chose to create a system that can transform waste paper and card into a state where it can be re-used. I spoke to family and friends and one of whom described a paper brick maker they use regularly. This product took paper pulp and compressed it into a burnable log. However the ones currently on the market are for single logs. My client has large volumes of waste paper and card. Is there a way to increase efficiency and produce more logs?

This evolved into my A-level project. I started by investigating a wide range of methods to compress the pulp. Manual, hydraulics and other electronic systems were considered. However due to limitations I Proceeded with a manual system.

I chose a method that applies the compressive force using a lead screw. This was extremely effective due to the ability to manipulate the lengths of the handle, which in turn changes the downwards pressure that can be applied to the pulp.

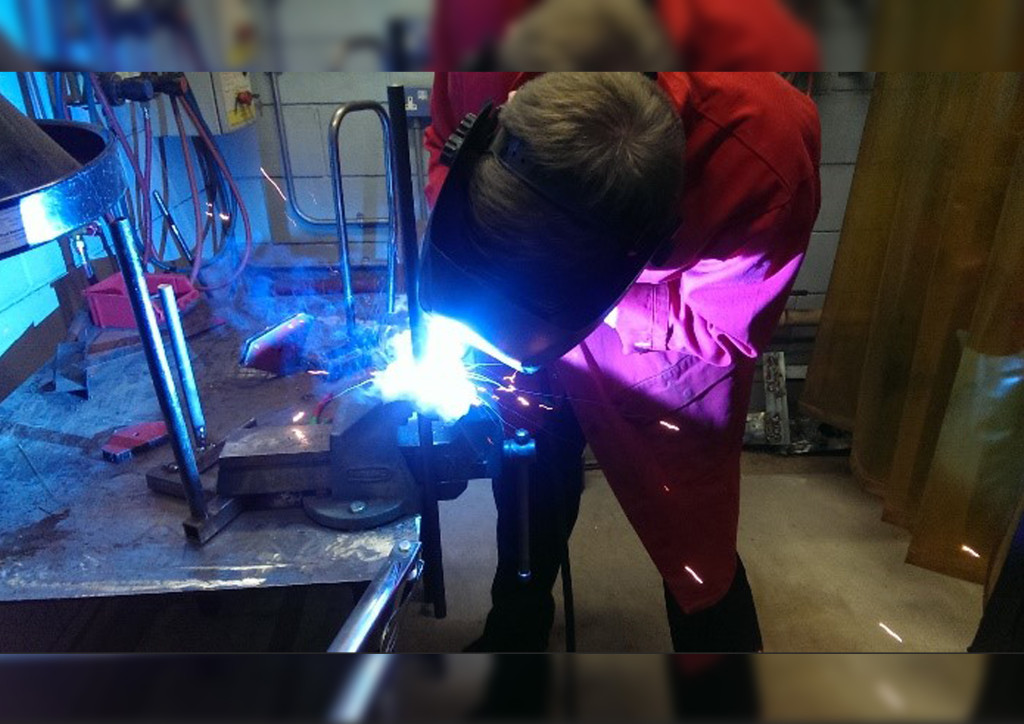

My design evolved and I began to make the system. The press was created out of mild steel due to it being relatively available with the necessary strengths to cope with the forces the system will undergo. Using a variety of fixing techniques the product was completed.

The final product was very successful. Upon evaluation only a few ideas were raised. Firstly the lead screw required a higher pitch, which would help speed up the system. Secondly despite the system working well it was a very repetitive procedure. Ways to automate it were investigated and would greatly improve the system.

The photos below show the progression through this project.